|

OHBA&MORITO Laboratory |  |

See recent activity here.

It is well known that materials consist of atoms. Most of materials have periodic arrangement of atoms. This periodic arrangement of atoms is called crystal. Real materials are made by an assembly of different-oriented crystals and different-structured crystals. The assembly of crystals is called texture. Properties of the real materials are affected by crystal structure and texture.

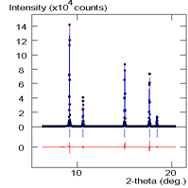

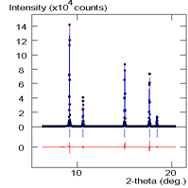

In our laboratory, crystal structures of martensitic materials and functional materials are studied by X-ray diffraction or neutron diffraction or electron macroscopy. Synchrotron radiation facilities, Photon Factory in Tsukuba and SPring-8 in Nishiharima, are utilized. Neutron facilities, JRR3 in Tokai and KENS in Tsukuba and others, are also utilized for our studies. Texture of materials is also studied by Scanning Electron Microscopy and related technique.

Materials studied in our laboratory are martensitic materials and other functional materials, such as rear-earth oxide perovskite and zeolite. Martensitic materials are used as an iron hardening and also as a shape memory and pseudo-elastic materials. The rear-earth oxide materials are expected as a use of cryogenic regenerator materials at low temperature.

'Martensite' is named after Adolf Martens, who studied ferrous alloy texuture

by optical microscopy at the end of 19th century. The crystal structure of ferrous alloy (iron) is face-centerd cubic and

tranforms into body-centerd tetragonal structure. The higher temperature phase is somotimes called 'parent phase' or 'austenite'

and lower temperature phase is called 'martensaite'.

Long history of martensitic transformation research revealed that the transformation

occurs not only in ferrous alloys but also in non-ferrous alloys .

Crystallographic studies revealed that parent and martensite have an orientation

relationship and that an interface between parent and martensite called

habit plane exist.

Further, defects, such as twins or stacking gaults, exist intrinsically

in the martensite.

Discovery of X-ray revealed that the transformation occurs without diffusion.

The characteristic textures of martensite are obtained by this diffusionless transformation process. Nowadays, the martensite transformation is understood to be the displacive

and the typical first-order transformation.

A shape memory effect relates to the martensitic transformation.

Although a study of martensite has a long history, a mechanism of the transformation

is still under investigation. Brief overviews of Professor Ohba's works related to martensite are summarized. Some of articles in the form of PDF files are available in this HP. Professor Morito has joined our group since 2005 Feburary. He has been studying texture of ferrous alloy using Electron Back Scattering Diffraction. The characteristic textures of ferrous alloys were classified into packets and blocks. He revealed the block in lath martensite consists of sub-block, whose

crystallographic results are useful for steel-hardening process.